Spiral tapes for lightweight construction – bicycle rims

14.10.2025

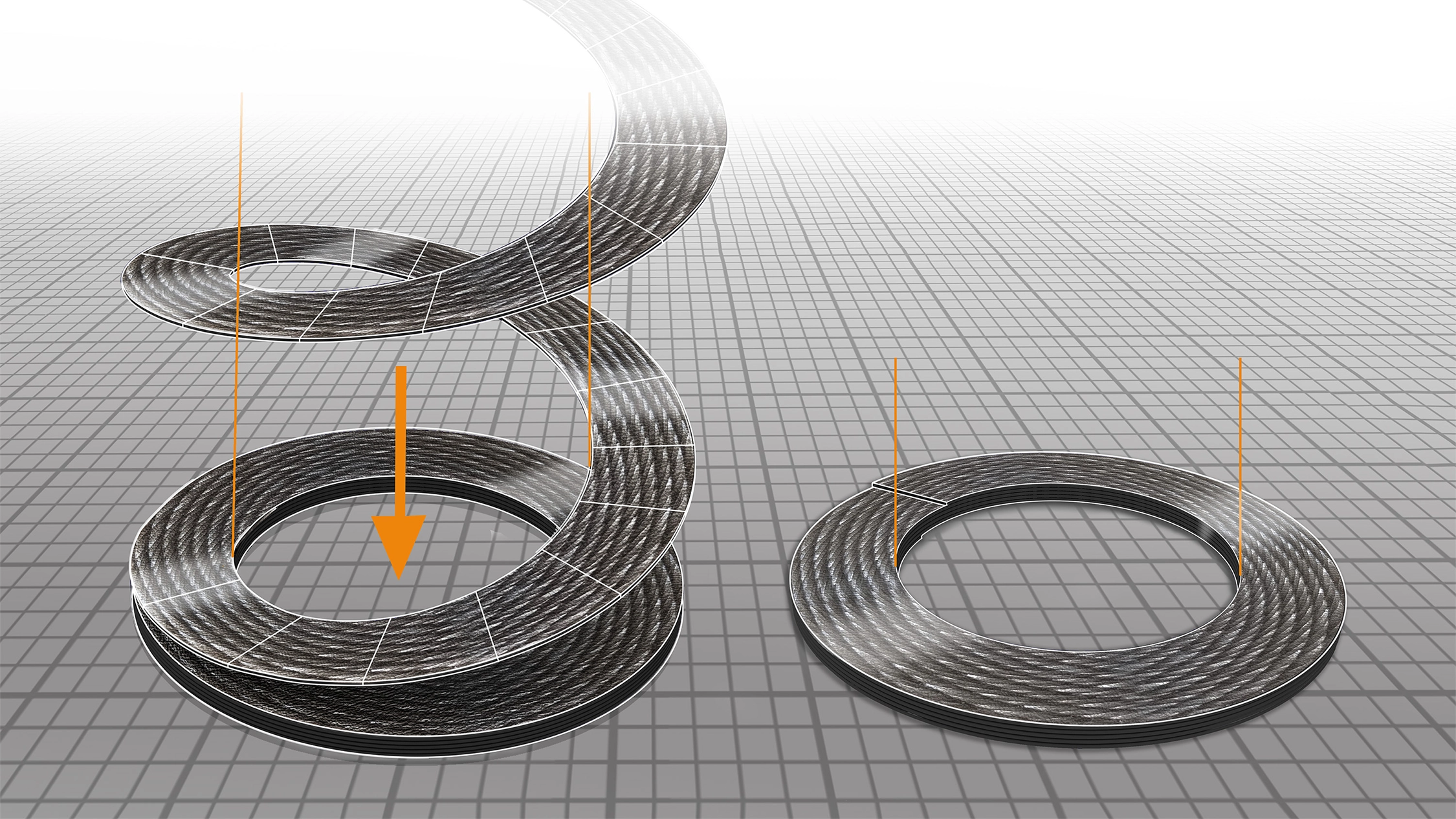

Spiral-shaped textiles as a base material – for carbon rims, among other things

Spiral tapes woven into shape by vombaur offer manufacturers of lightweight components an ideal material for round components that can also be processed efficiently.

Maximum lightness, maximum strength

Our spiral tapes are woven directly into shape. The result: spiral tapes without cut edges and therefore without severed fibres. The fibres in the spiral tapes are arranged in a circular pattern and the tapes are woven in one piece to form an adequate number of layers. This ensures maximum strength, maximum lightness and maximum variety of shapes. The ideal basis for bicycle rims of the highest quality: extremely light, extremely strong, extremely resilient.

Top textile performance for top sporting performance

Not all rims are the same. Every type of bicycle has different requirements in terms of profile height, width, diameter and shape of the rim. vombaur individually adjusts the diameter of the spiral band to the diameter of the rim for each project. Strength, flexibility, weight per unit area, fibre type and fibre distribution are also individually configured. Thanks to the high density and stability of the spiral bands woven into shape, the amount of material used is reduced compared to other manufacturing processes and materials, thereby reducing weight. This reduces the effort required by the cyclist. Our spiral tapes deliver top textile performance for sporting success.

High-tech textiles for high-tech components: Carbon UD tape from vombaur

Efficient energy conversion

Our form-fitting fabrics significantly reduce the manufacturing costs of the rims. The spiral tapes automatically adapt to the predefined shape. What’s more, they prevent material waste that would otherwise result from cutting. This conserves resources.

Spiral tapes for high performance in lightweight construction

- High efficiency and precision in processing into composite components

- Maximum resource utilisation

- Individual configuration of the spiral tape (shape, strength, flexibility, weight per unit area, fibre type and distribution)

- As UD or 0/90° quality

- From an inner diameter of approx. 50 mm

- Standard width up to 300 mm

- Consistently high quality

- Reliable reproducibility

„Carbon rims have been the standard in professional cycling for many years. Even amateur cyclists are increasingly switching to bikes with carbon rims,” explains Sales Manager Johannes Kauschinger. „vombaur specialises in straight, curved, and spiral tapes made from virtually any fibre material. Our carbon spiral tapes have been used as a reliable base material for many years wherever low weight, high strength, and exceptional reliability are required.”