Filtration at its finest

14.04.2025

Filtration tubulars for the demanding requirements of the chemical industry

Whether in the production of speciality chemicals and additives, in refineries or in petrochemical plants: the demands on solid-liquid filtration in the chemical industry are extremely high. Depending on the application, the filtration systems are exposed to heat, acids, regular cleaning processes, high mechanical load or other demanding environmental and process conditions. This requires high-quality and robust filtration textiles.

We develop customised technical narrow fabrics for filters and filter systems for our customers in the chemical industry. The high-quality filter sleeves are seamless round woven. This makes them particularly heavy-duty and robust.

The optimum material for every application

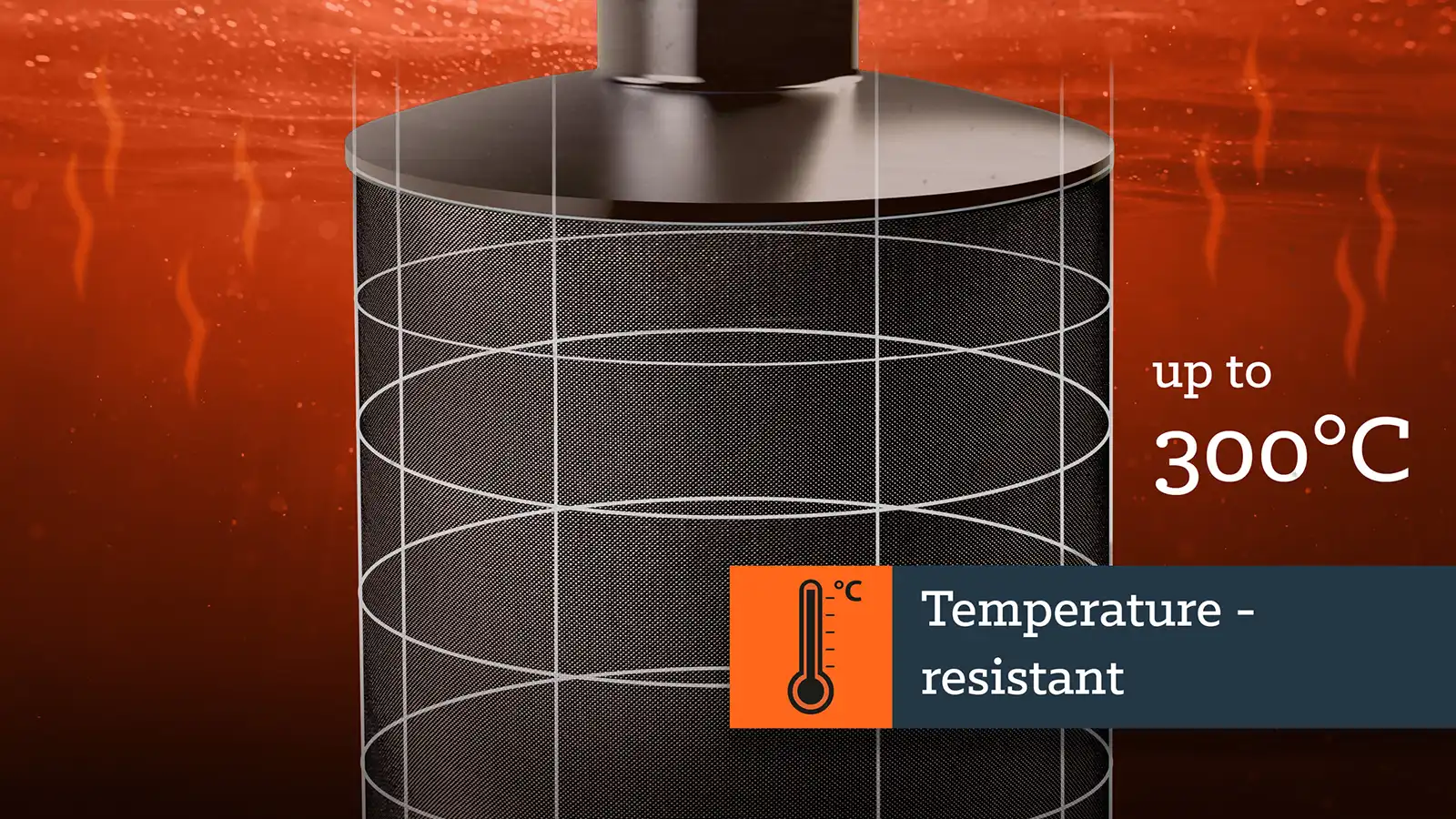

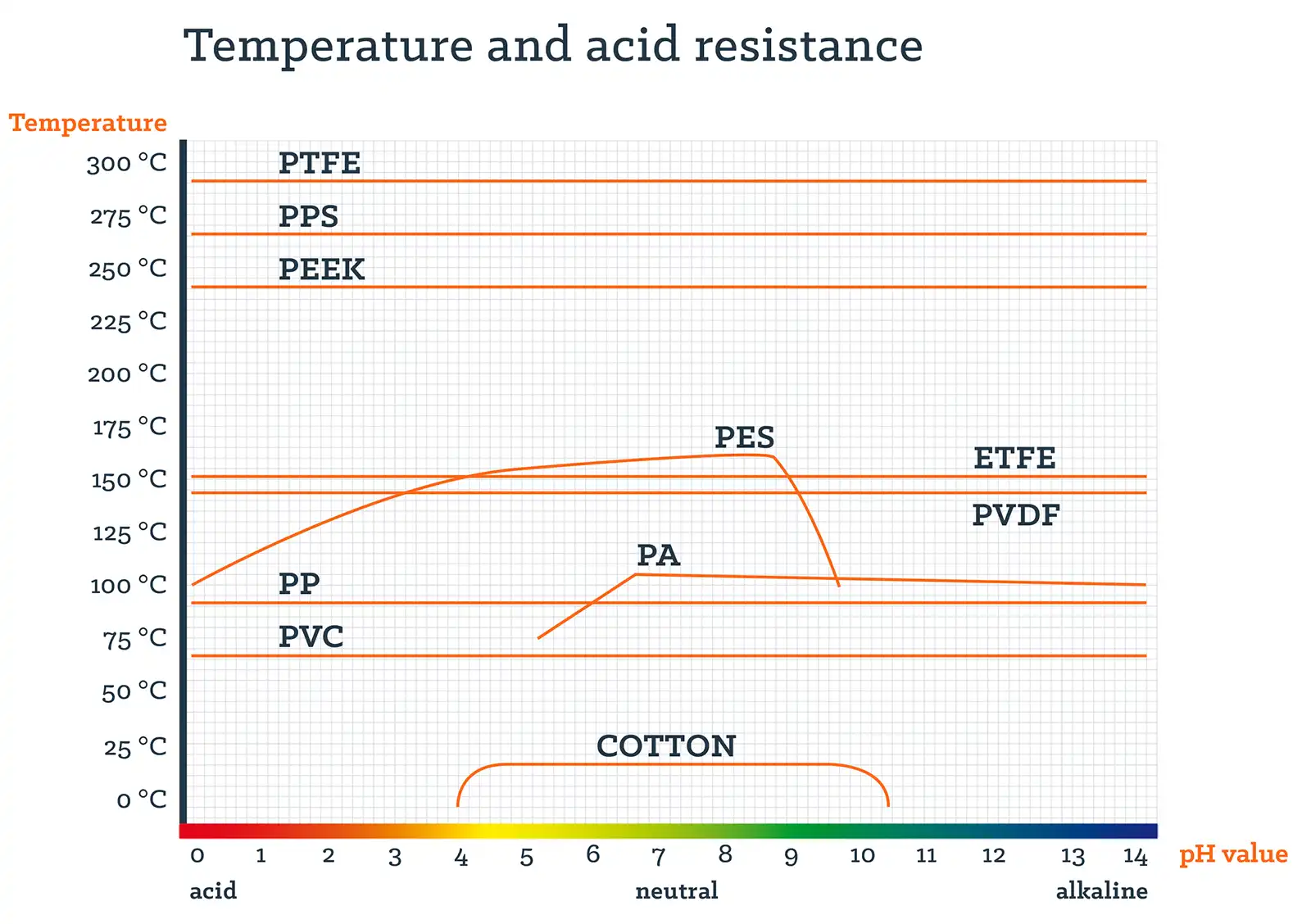

In the manufacture of the woven tubulars we use high-tech materials, which are ideally suited to the demanding filtration tasks in the chemical industry. They are characterised by exceptional resistance to bases and acids. Depending on the filtration requirements, we use high-performance fibres made of PEEK, ETFE, PVDF, PP or PES, for example. On special manufacturing plants the materials are woven into seamless filter sleeves, which have an extreme temperature resistance of up to 300°C.

Precise filtration properties

Thanks to their seamless construction, our filter sleeves have decisive advantages over ready-made filtration textiles. As the round woven tubulars have no seams or welds, the material thickness and permeability are identical all around. The tubulars therefore ensure uniform flow and filtration properties. The filtration result can be precisely and reliably defined. In addition, this design makes the filter sleeves exceptionally heavy-duty and durable, as they are free from unwanted break points caused by seams or welds in the longitudinal direction. The filters and filter systems are therefore highly process reliable in use and extremely economical and sustainable.

„We have been supplying filter manufacturers with filtration textiles for the chemical industry for decades and know the industry’s filtration requirements exactly,“ explains Sales Manager Maren Zurek. „We always configure the functionality of our textiles individually and on a project-specific basis. This means that our customers receive a first-class product and benefit from highly functional filter sleeves.’

Highly functional and reliable

- Identical material thickness all around

- Identical flow properties all around

- Durable and wear-resistant

- Temperature-resistant up to 300°C

- High process reliability

Filtration tubulars for the demanding requirements of the chemical industry

Whether in the production of speciality chemicals and additives, in refineries or in petrochemical plants: the demands on solid-liquid filtration in the chemical industry are extremely high. Depending on the application, the filtration systems are exposed to heat, acids, regular cleaning processes, high mechanical load or other demanding environmental and process conditions. This requires high-quality and robust filtration textiles.

We develop customised technical narrow fabrics for filters and filter systems for our customers in the chemical industry. The high-quality filter sleeves are seamless round woven. This makes them particularly heavy-duty and robust.

The optimum material for every application

In the manufacture of the woven tubulars we use high-tech materials, which are ideally suited to the demanding filtration tasks in the chemical industry. They are characterised by exceptional resistance to bases and acids. Depending on the filtration requirements, we use high-performance fibres made of PEEK, ETFE, PVDF, PP or PES, for example. On special manufacturing plants the materials are woven into seamless filter sleeves, which have an extreme temperature resistance of up to 300°C.

Precise filtration properties

Thanks to their seamless construction, our filter sleeves have decisive advantages over ready-made filtration textiles. As the round woven tubulars have no seams or welds, the material thickness and permeability are identical all around. The tubulars therefore ensure uniform flow and filtration properties. The filtration result can be precisely and reliably defined. In addition, this design makes the filter sleeves exceptionally heavy-duty and durable, as they are free from unwanted break points caused by seams or welds in the longitudinal direction. The filters and filter systems are therefore highly process reliable in use and extremely economical and sustainable.

„We have been supplying filter manufacturers with filtration textiles for the chemical industry for decades and know the industry’s filtration requirements exactly,“ explains Sales Manager Maren Zurek. „We always configure the functionality of our textiles individually and on a project-specific basis. This means that our customers receive a first-class product and benefit from highly functional filter sleeves.’

Highly functional and reliable

- Identical material thickness all around

- Identical flow properties all around

- Durable and wear-resistant

- Temperature-resistant up to 300°C

- High process reliability

Seamless round woven filtration textiles from vombaur: ideal for the demanding tasks in the chemical industry

Filter sleeve made of PTFE: for temperatures up to 300 °C and all pH values