Spiral tapes for mechanical engineering

14.10.2025

Spiral-shaped textiles as a base material for industry

Materials suitable for circular geometries

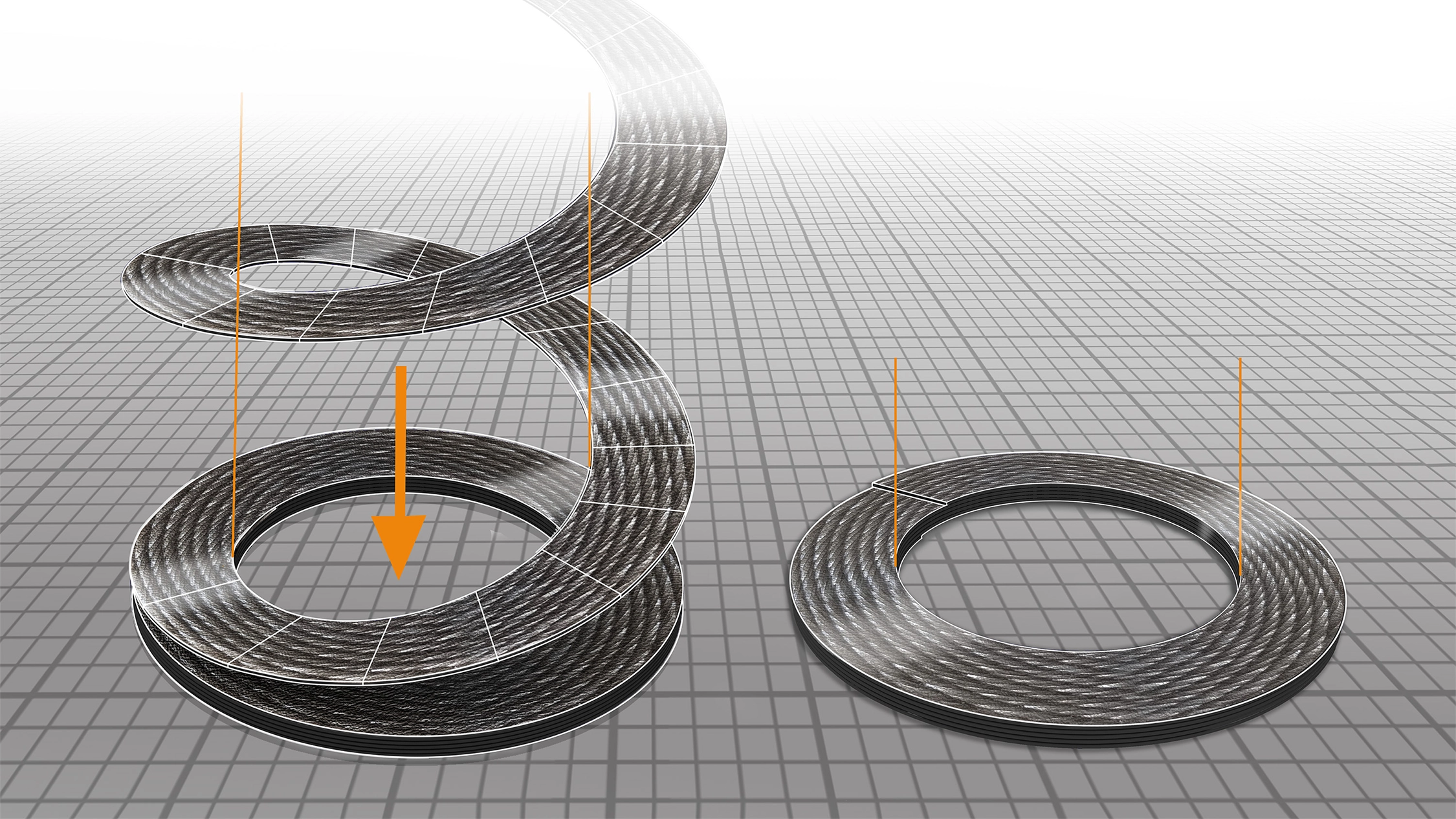

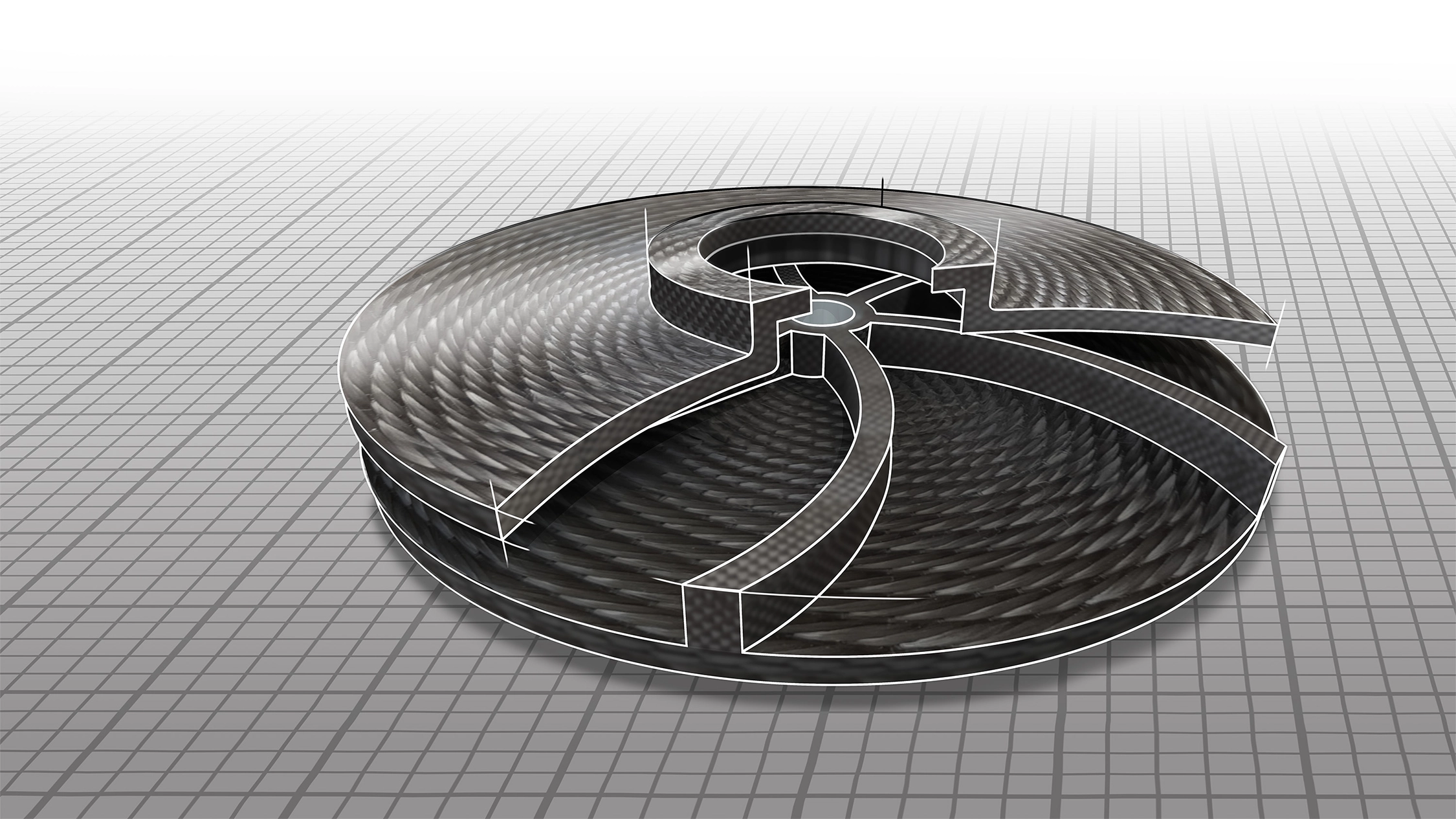

For our industrial customers we develop carbon and glass spiral tapes as a base material, including pump manufacturers. The textiles are woven into shape. This creates round, curved or spiral geometries without severed fibres at the cut edges. The result: particularly strong and durable fabrics as a basis for high-strength components – even in round and curved shapes. The form-fitting textiles reduce manufacturing costs. What’s more, the spiral tapes avoid material waste that would result from cutting. This conserves resources.

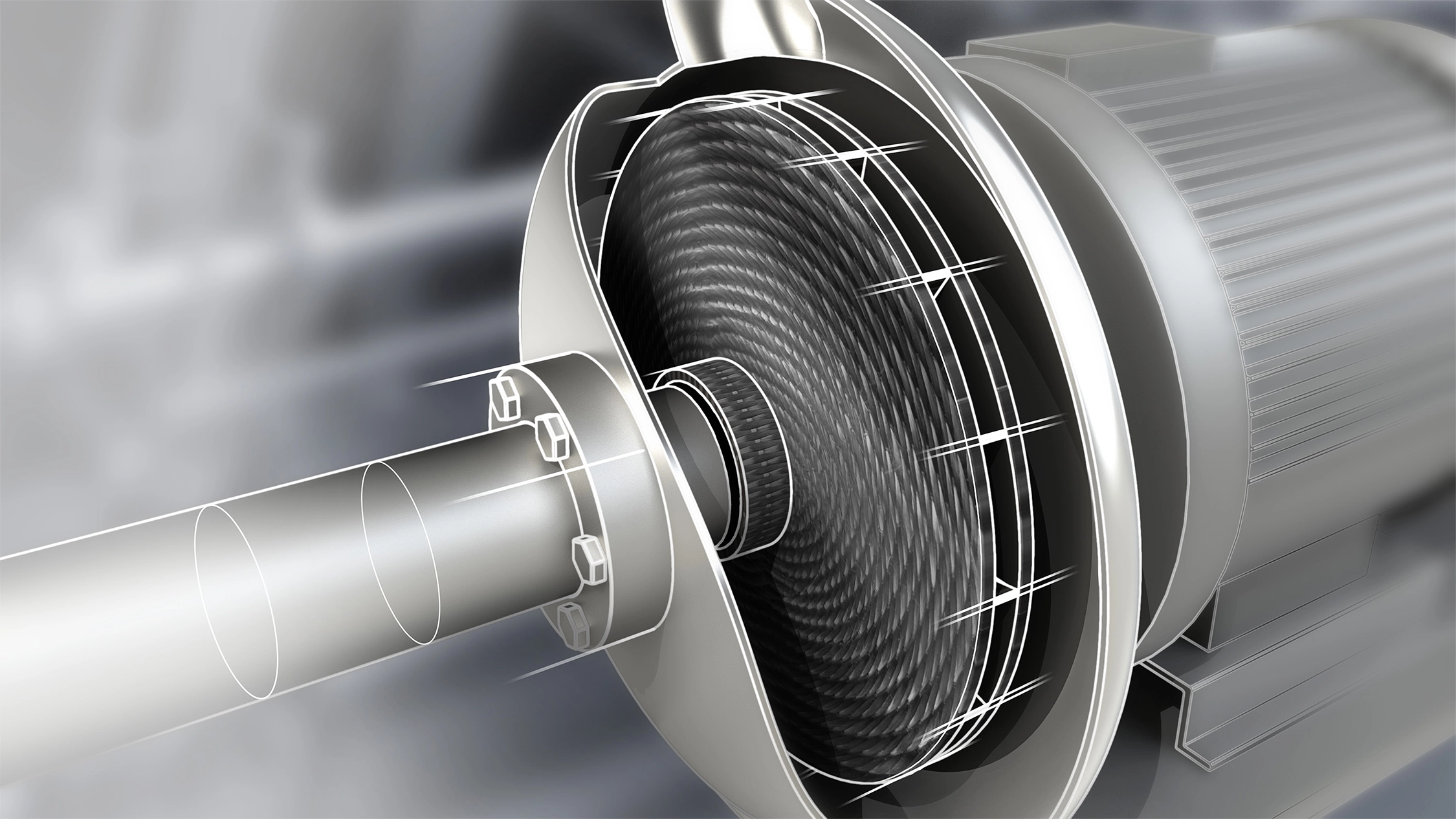

Pump impellers cool boat engines, power hovercrafts and transport food through production facilities. They are used in numerous industries. The rotors move within a precisely fitting housing. Manufacturers require high-quality, durable components to ensure that the pumps

Spiral tapes for efficient energy conversion

The filaments of our spiral tapes woven into shape are arranged in a circular pattern. This filament orientation facilitates the start-up of the rotating discs and reduces the energy required for movement.

Strong performance – thanks to first-class properties

- High efficiency and precision in processing into composite components

- Maximum use of resources

- Individual configuration of the spiral band (shape, strength, flexibility, weight per unit area, fibre type and distribution)

- As UD or 0/90° quality

- From an inner diameter of approx. 50 mm

- Standard width up to 300 mm

- Consistently high quality

- Reliable reproducibility

- Individually specified and ready-to-use discs on request

„As specialists in straight, curved, and spiral tapes made from virtually any fibre material, we can offer our customers in mechanical engineering conformable fabrics in numerous geometries,” explains Sales Manager Johannes Kauschinger. “Using our spiral fabrics as a base material, manufacturers enhance the quality of round lightweight components such as impeller discs – and increase their efficiency in production as well as during operating.”