Clean. Safe. Sturdy.

21.01.2021

Filtration textiles by vombaur

From the drinking water and food industries through water management and mining to the automotive and aviation sectors, mechanical filtration processes are used in almost every industry. As different as the methods, dimensions and special requirements of the filtration process are in each case – technical textiles and often tubular filters are almost always used. This means that our tubular filters and narrow textiles by vombaur contribute to the safe and reliable separation or treatment of substances in the widest variety of filtration processes.

Individual solutions

The requirements placed on the textile, the material, the flow rate and the loading capacity of the filters depend on the respective use: a tubular for dewatering soil needs to withstand different forces than a tubular filter for the beverages industry. On the other hand, the latter needs to meet the highest hygiene standards. Because the requirements are so individual, we develop customised filtration textiles for our customers all over the world.

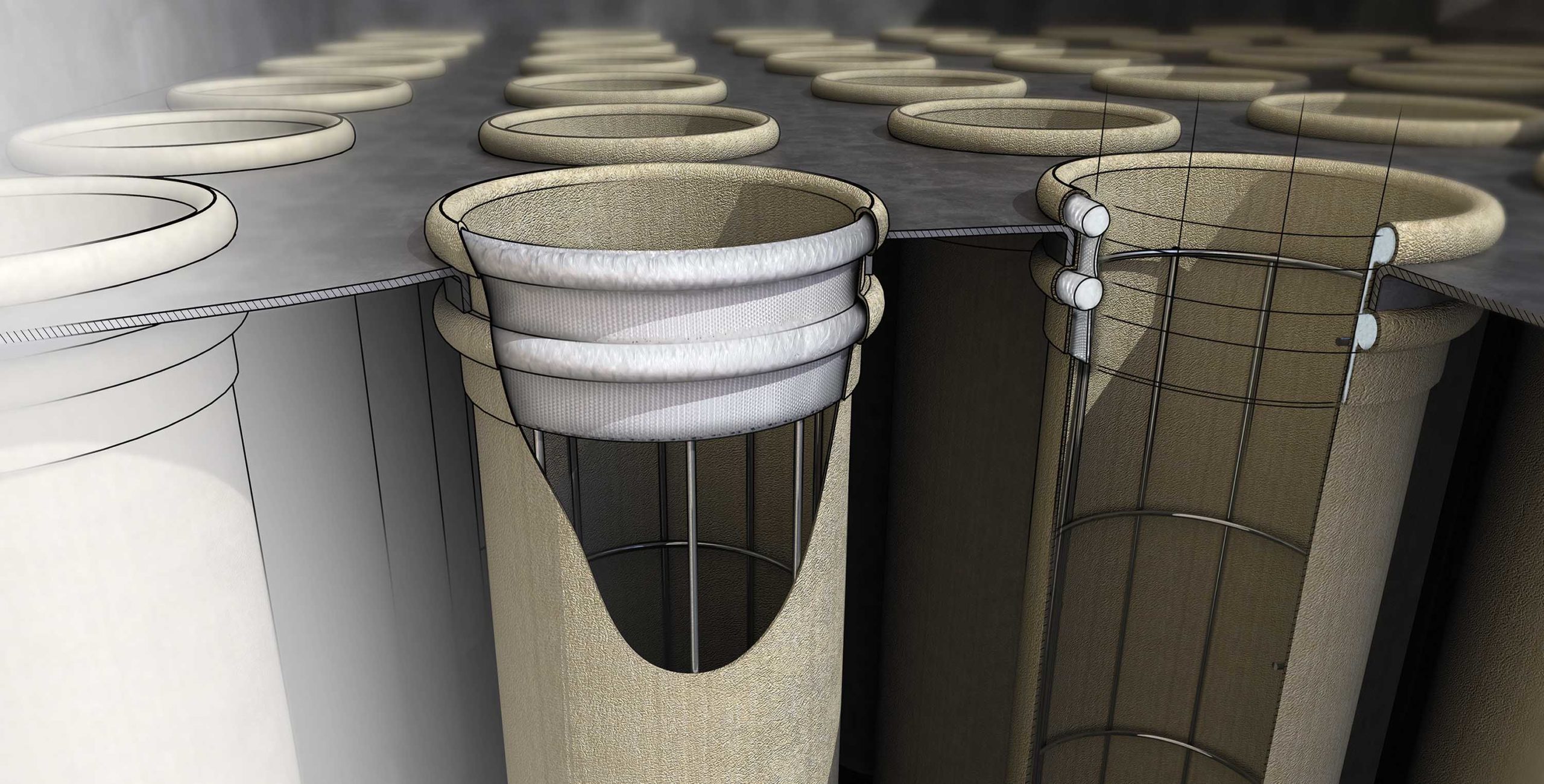

Seamless round woven textile tubular, e. g. for dewatering

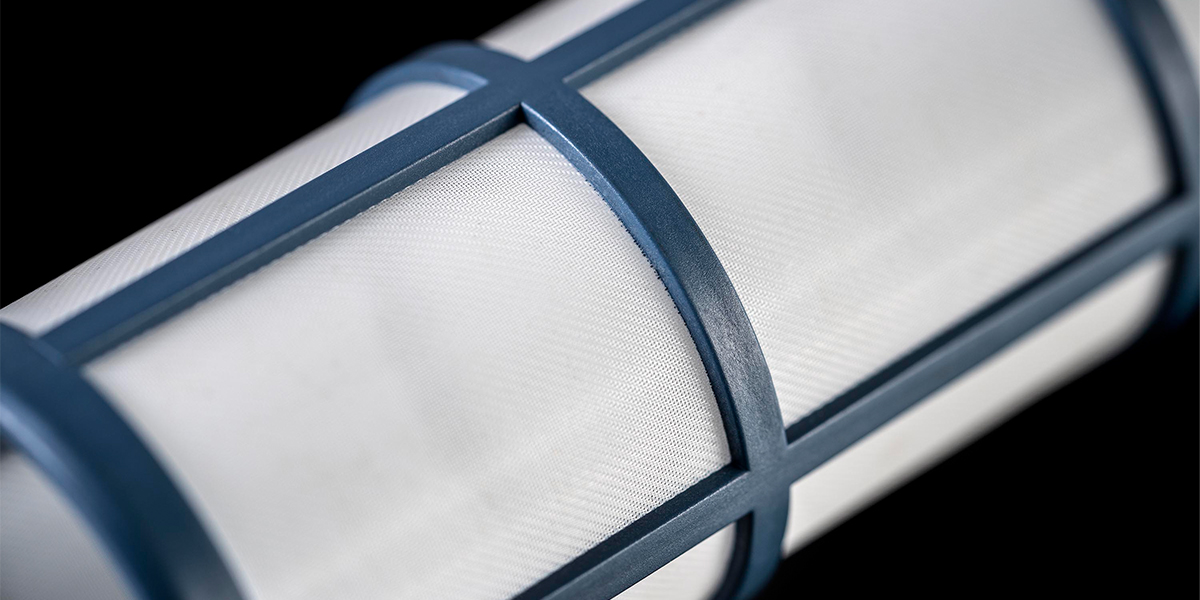

Multilayered seamless round woven tubular filter, e. g. for marine engines

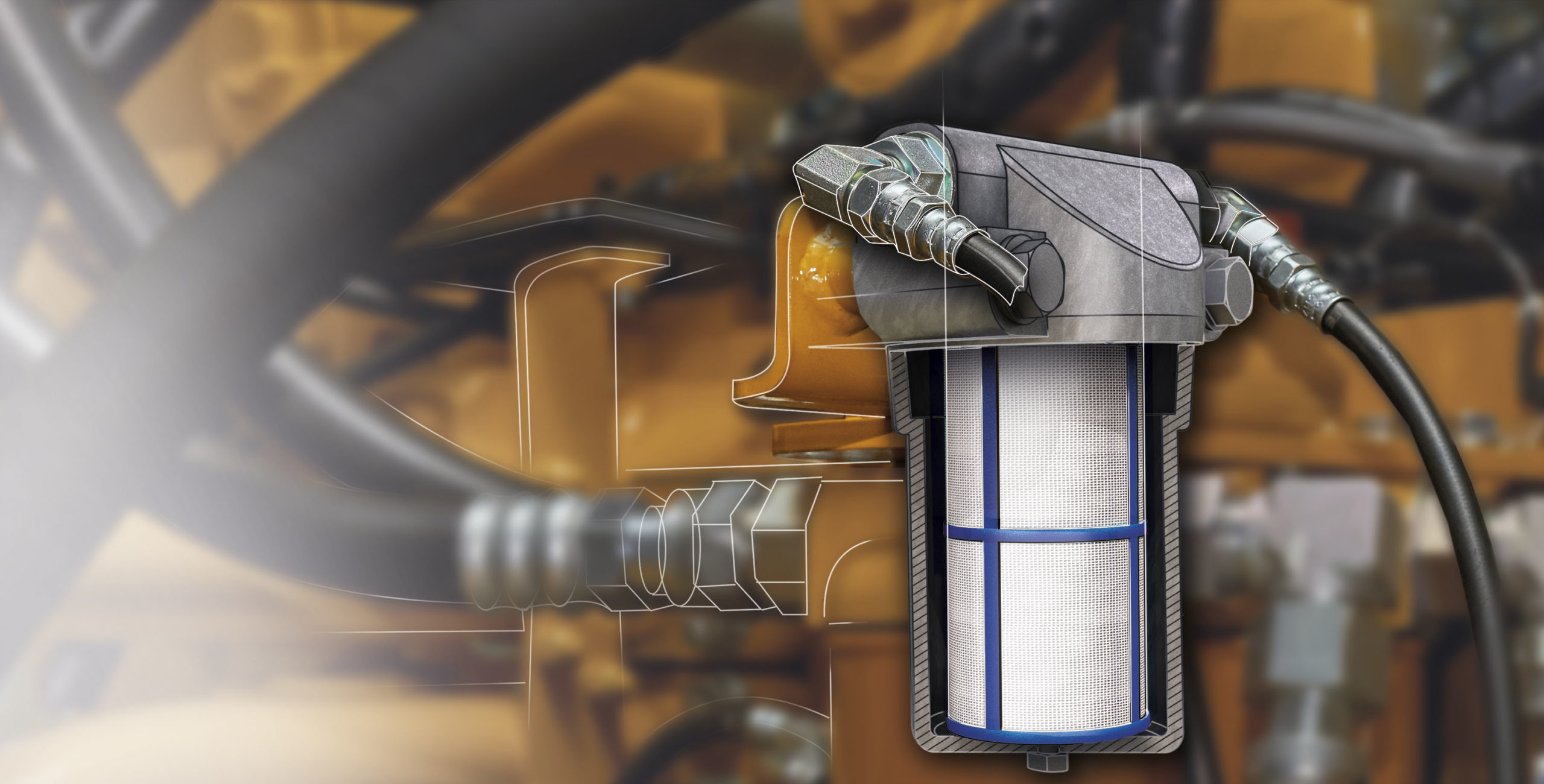

Seamless round woven tubular oil filter in cartridge, e. g. for automotive engines

High-quality beading tape,

e. g. for fabricating filter media

Seamless tubular filters

But no matter how individually the solutions are developed, and no matter what the tubular filters are made of and for what purpose we produce them, they all have one thing in common: they do not have a seam. Because at vombaur, filter media are round woven seamlessly on unique looms. As a result, they have identical surface properties all around and over the entire length, such as flow rate, loading capacity, shrinkage behaviour or material thickness. No seams, no varying thicknesses, and no unwanted breaks to affect the production of the filter or the filtration process – a decisive advantage over fabricated tubular filter.

Narrow textiles for fabricating filter media

For the fabrication of filter media, the industry needs high-quality narrow textiles that cleanly and reliably seal, reinforce, stabilise … A task in which high-quality tapes and belts ensure safety for our customers.

“We manufacture our narrow textiles from a wide variety of high-tech yarns. Sometimes monofilament yarn is used, sometimes multifilament, sometimes spun yarn. Like the type of weave, we select the raw materials depending on the function they need to fulfil,” emphasises Sales Manager Gert Laarakker. “So that our filtration textiles reliably perform the job they are supposed to perform. Clean. Safe. Sturdy.”

Filtration textiles by vombaur

Photos: vombaur