Clean. Safe. Precise.

16.04.2021

Filtration in the food industry – with woven tubulars and tapes by vombaur

From sugar beet to granulated sugar, from grapes to Pinot gris, from yeast and hops to beer, from rapeseed to edible oil, from cocoa fruit to chocolate … – filters are almost always involved at some point in the food production process. The tasks is often solid-liquid separation, and it is often textiles that serve as filtering agents. A filter material with thousands of years of tradition: wine was already filtered through cloths in ancient Egypt.

High demands on filtration media

Modern filter media are high-tech products. We weave innovative high-performance fibres into individually specified, high-performance filter media on unique facilities. They do have precisely defined properties. Thus, they reliably meet the respective filtration requirements and – of course – also the high demands of the food industry. The yarns are suitable for food filtration and are FDA/EN-approved on request. We also offer tubular textiles that are FDA/EN-approved.

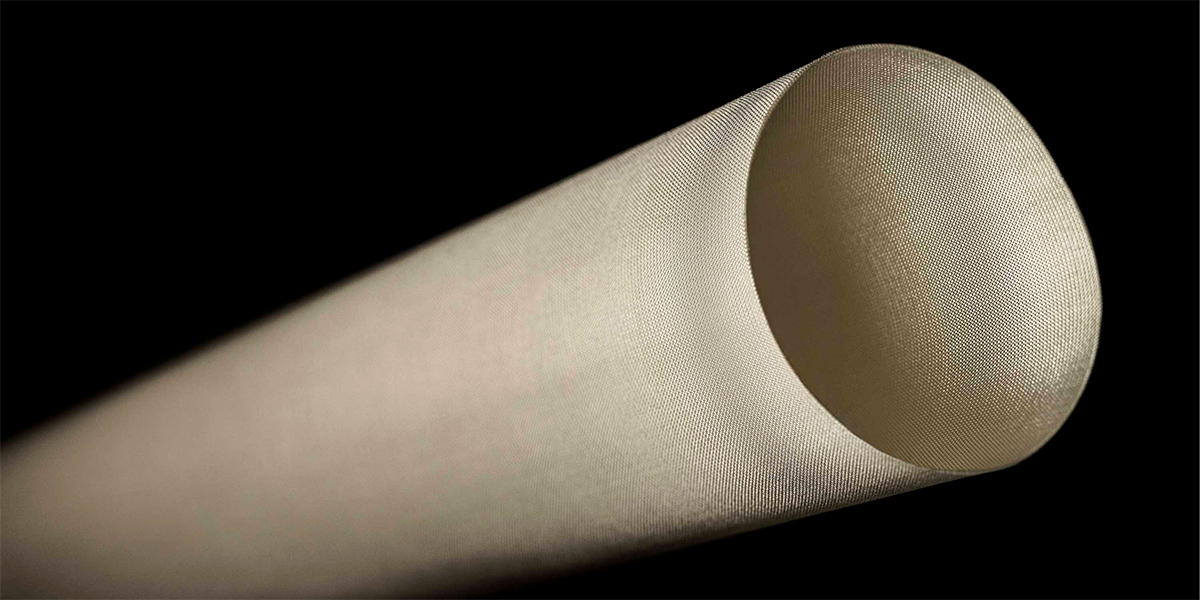

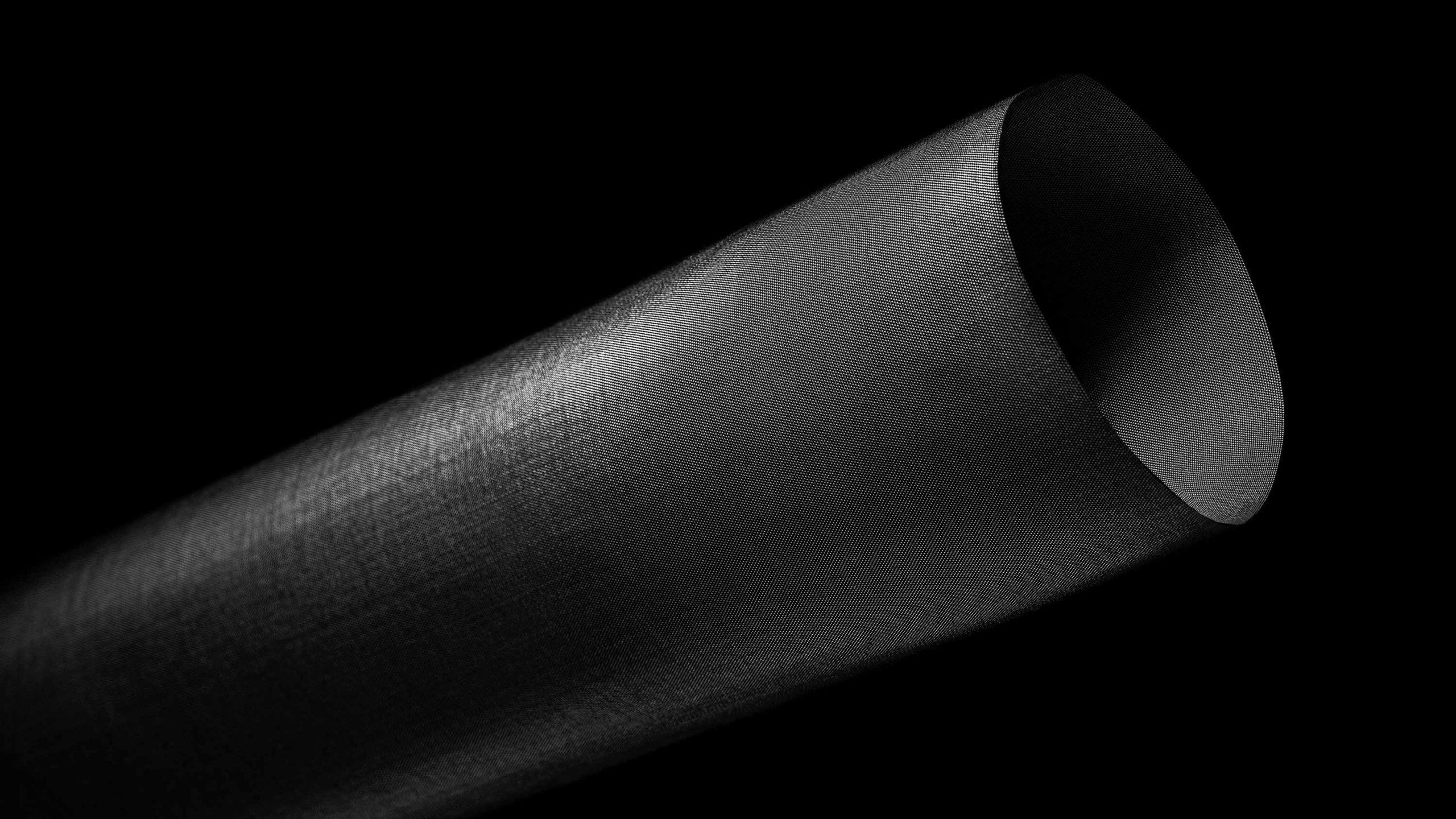

No seam, smooth process

One thing in particular distinguishes our filter media: they do not have a seam, because they are seamlessly round woven. As a result, our tubular filters have identical surface properties all around and over their entire length, such as the flow rate, load capacity, shrinkage behaviour or material thickness. With vombaur filtration textiles, there are no seams, bulges or breaks that could impair or interrupt the filtration process.

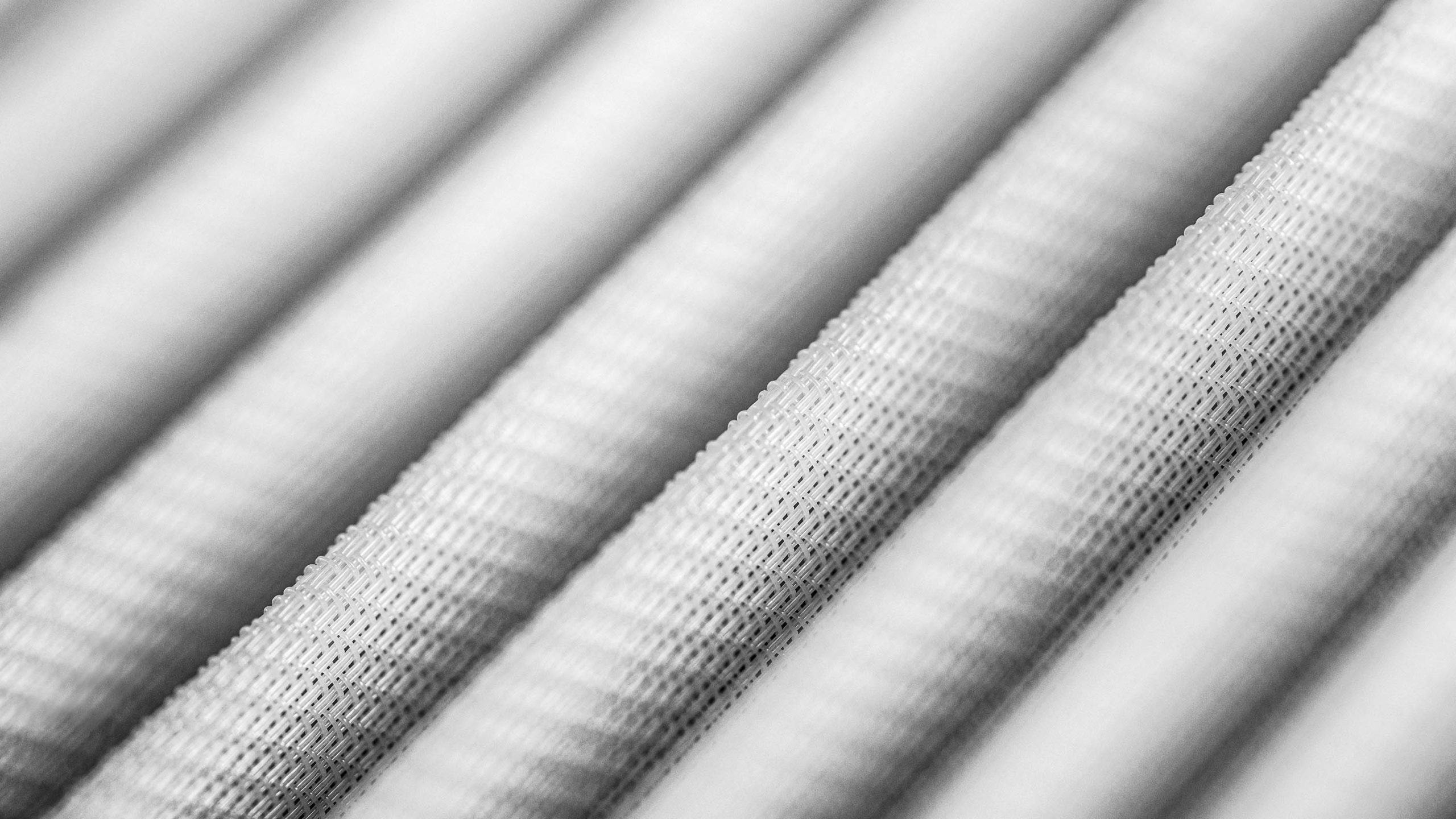

The optimum weave technique for every application: here a pleated filter fabric in 2/2 twill weave.

The optimum weave technique for every application: here a pleated filter fabric in 2/2 twill weave.

From viscous to aqueous

Different filtrates, different filtration media. Clearly, filtering sugar beet syrup will require a different filter medium from one for tap water. Decisive for the development of the perfect filter medium – regardless of whether it is a tubular or belt textile – is not only the yarn type but also the weaving technique: the taffeta weave forms a tight textile bond with high displacement resistance. The atlas weave ensures a particularly smooth surface of the filter textile. The filter cake comes off the surface more easily. And the twill weave is also used for special filter properties.

Development partner for high-performance filtration textiles

Whether with our seamless round woven tubular filters or with our woven tapes for fabricating filter media: your requirements drive our product development. The material, fabric type, weaving technique and finishing are selected as a function of what the filter medium needs to achieve. As a development partner, we provide samples and manufacture filtration textiles for the food industry in close cooperation with the customer – and for the strictest requirements.

Strict quality requirements apply for filtration in the food industry – round woven tubular filters and tapes for fabricating them from vombaur meet those requirements.

Strict quality requirements apply for filtration in the food industry – round woven tubular filters and tapes for fabricating them from vombaur meet those requirements.