„Typical of seamless solutions“

20.06.2020

Seamless engineered solutions for challenging tasks: our round and shaped woven textiles

Technical narrow textiles fulfil an important function in innumerable products and processes. Filtering foods, seals in the chemical industry, reinforcing components in aerospace engineering … – the applications in which technical textiles are used are are often particularly critical and challenging.

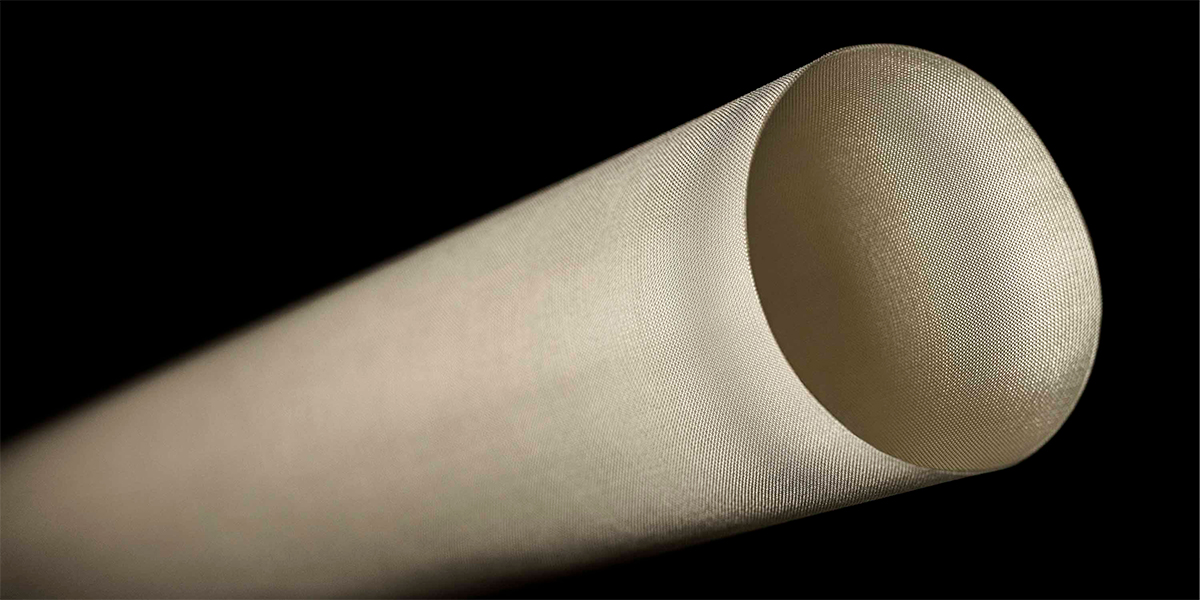

Uniform surface properties

At vombaur, we weave our tubulars and 3D wovens on looms specially developed for this purpose. The result is woven tubulars made of high-performance fibres, which are extraordinarily resilient because they have no seams or welds and therefore no undesirable weak spots. Another, often decisive advantage: our seamless tubular textiles have identical surface properties over the entire circumference and length. vombaur thus offers a perfectly fitting and safe solution for demanding tasks – in numerous industries.

Uniform filtration properties

For filtering oil and water, our round woven tubulars offer a decisive advantage compared with fabricated tubes: our seamless tubular woven fabrics have identical surface properties, and thus identical filtration properties, all around. Flow rate, loading capacity, shrinkage behaviour, material thickness – our filter media exhibit these central properties over the entire surface of the tubular. The filtration results are thus precisely and reliably defined over the entire surface of the filter.

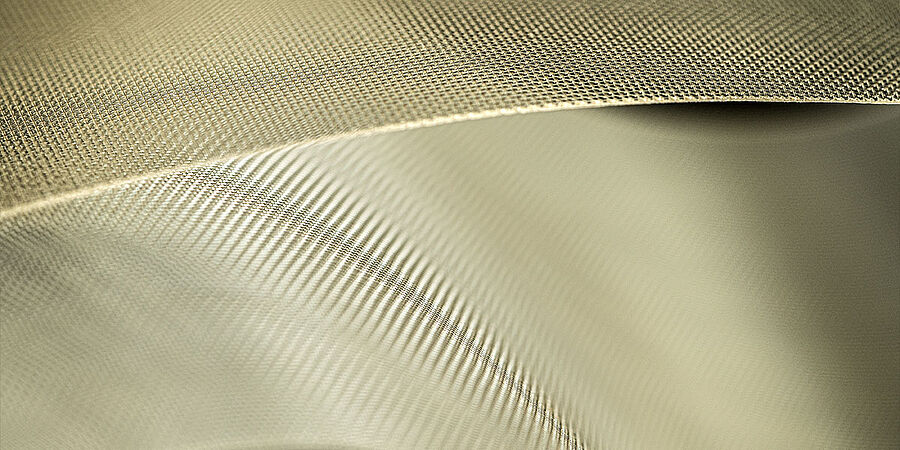

High performance tapes and high tenacity components

Composites made of seamless wovens by vombaur are used wherever low weight and high strength are required – from flat wovens through UD tubes to preforms. Our woven tapes made of carbon, aramid, glass or hybrids are specified to perfectly fit the task in hand. As are lightweight parts made of vombaur textiles and special resin systems. As the high performance fibres are woven directly into shape or round woven, the composites are characterised by exceptional strength and stiffness. The variety of our tapes, shapes and profiles ranges from hollow chamber structures to star profiles, from extremely narrow textiles for orthoses to large-format special shapes for reinforcing wings in aviation or aerospace applications.

Extremely lightweight, extremely loadable: perfectly fitting composite textiles by vombaur, e.g., for automotive applications

Woven tubulars for critical functions

Due to their constant material thickness and uniform properties – over the entire surface and over the entire length – our seamless woven tubulars are particularly resilient and durable. This is supplemented by the high burst resistance of our seamless industrial textiles. This explains why vombaur textiles are particularly used for critical functions in industry. Wherever the weak spots of fabricated textiles pose risks, our seamless woven technical textiles offer a perfect fit and a reliable solution. From sensitive continuous conveyor belts made of polyamide to durable drainage sleeves for the construction industry, from heat-shrink tubulars made of PVDF to high tenacity cut protection belts for load handling.

Constant and precise: Industrial textiles by vombaur, such as timing belts and continuous conveyor belts

Development partner for high-tech engineered solutions

We use high-performance fibres made of a wide variety of materials for our seamless engineered solutions. “Like all textile specifications, we also define the raw materials to suit the mechanical, chemical and thermal loads in each use case,” as CEO Peter vom Baur emphasises: “We are development partners: together with and particularly for our customers, we develop seamless, round woven, high-tech tubulars and tapes that fulfil very special and demanding functions. Typical of seamless solutions.”