Up and running: High-tech products for industrial processes

09.05.2023

The potential of textiles as a tool for industry is still underestimated by the general public – and also by some manufacturers. There are a great many possibilities in technical textiles – including, and particularly, for movement processes: the properties of textiles can be put to excellent use in areas where machine motion sequences need to run smoothly and precisely. The areas of application and advantages of technical textiles are therefore enormous, especially in mechanical engineering.

vombaur has been developing customised textiles for industry for decades. As a specialist for seamless round woven narrow textiles, we have the special technical equipment to produce individual textile round and shaped fabrics for a wide range of end applications. Depending on the project requirements, we adapt our weaving machines to create textiles with the required dimensions and properties.

The most important industrial applications of our narrow textiles include conveyor belts and plain bearings. However, they are also used in industry as webbing, auxiliary tapes, conductive tapes and coating belts for reinforcements.

Seamless tubulars for high-precision conveyor belts

vombaur’s seamless round tubulars are used as conveyor belts in areas where high precision is required during transport. We weave the tubulars here from different materials depending on the application. Temperature, running speed, required adhesion properties – all this and more has an influence on the choice of material, its equipment, and all other specifications.

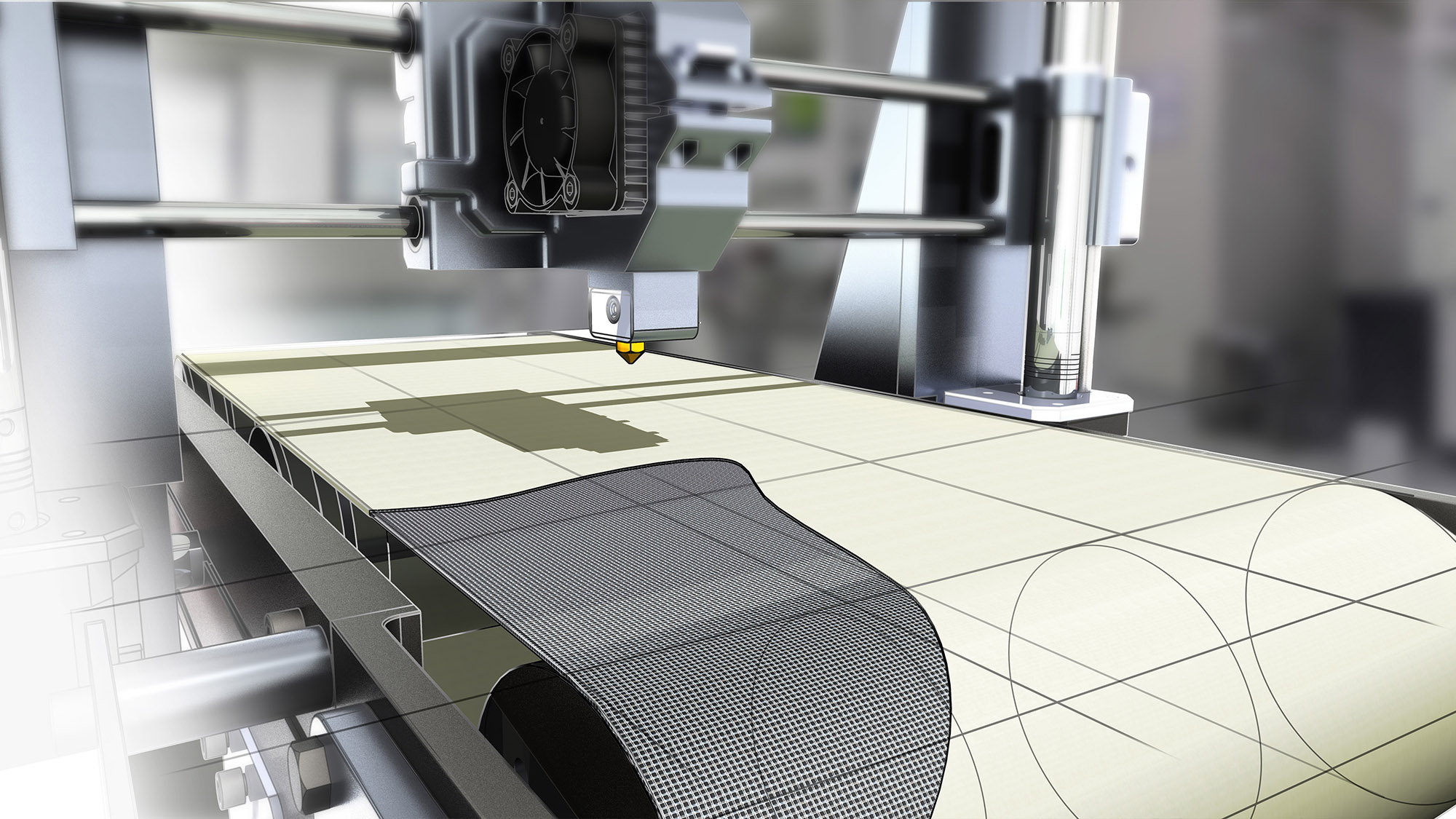

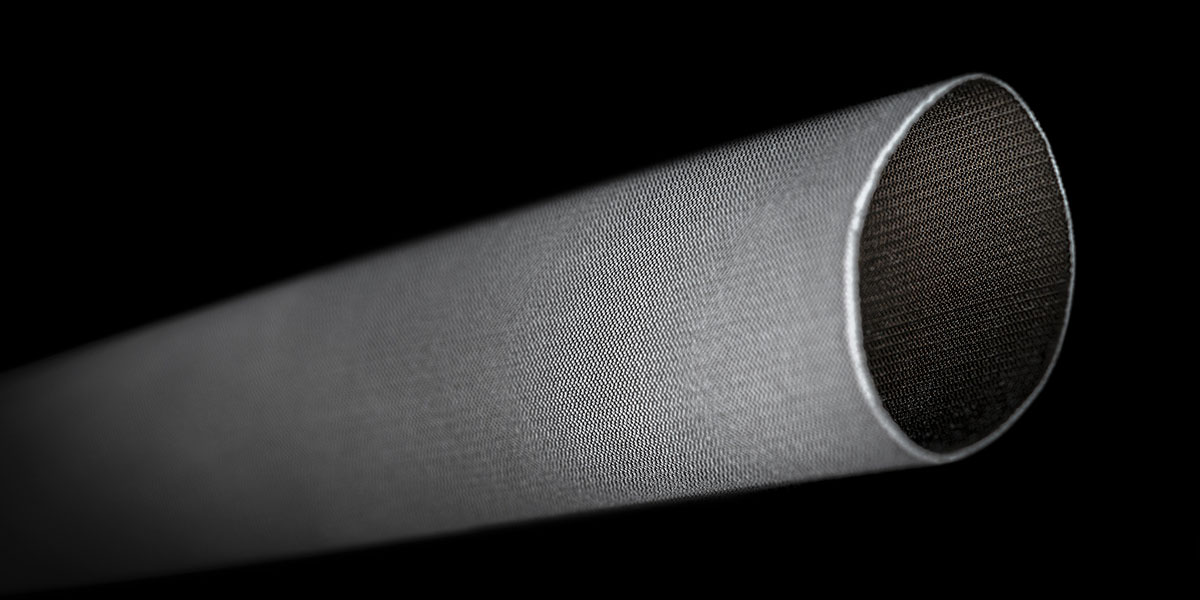

Our high-precision conveyor belts are used in machine and equipment construction. In technical devices such as printers, the conveyor belts ensure that the goods being transported get to exactly where they are needed. Our tubular fabrics place the goods with high precision. We achieve this precision thanks to the constant material thickness and running properties of our round woven tubulars, because neither seams nor bulges change the surface texture – they work evenly and precisely.

Round woven tubular with uniform running properties as a coating belt

Hem stitched belts for the precise fabrication of conveyor belts

Hem stitched belts made of materials such as PES, PP, PA, PEEK and PPS are suitable as fabrication aids for conveyor belts. The fabricated textiles have custom-fit properties that are matched to the conveyor belts.

vombaur’s round woven conveyor belts

Seamless tubulars for maintenance-free plain bearings

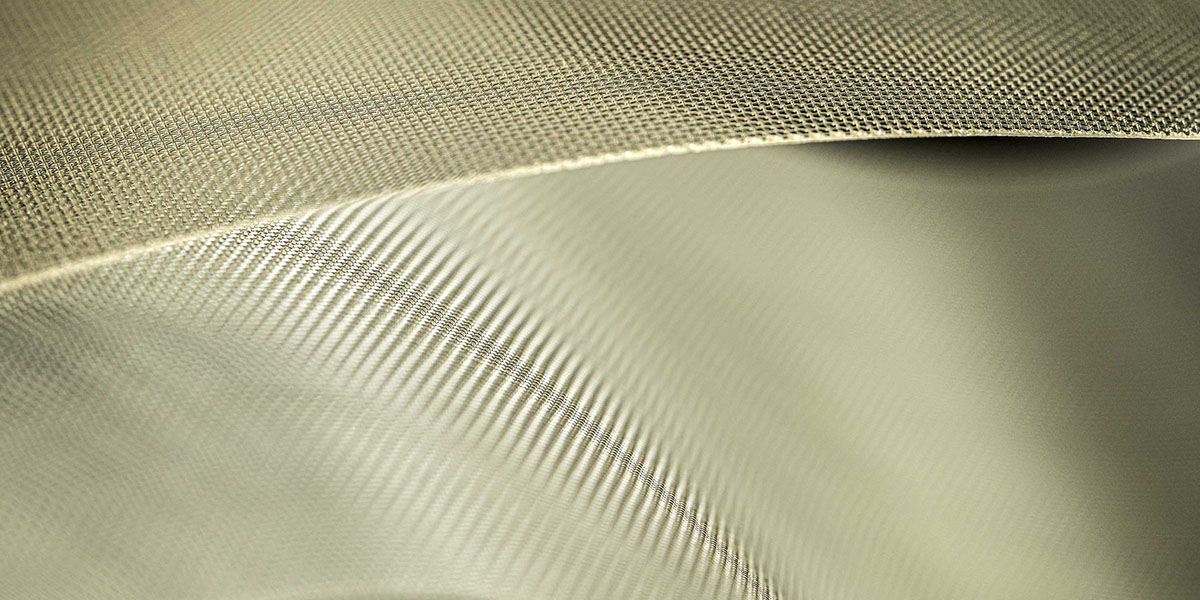

We develop two-layer woven tubulars made of high-tech fibres for use in plain bearings. The tubulars are usually woven from PES on the outside and are therefore very adhesive. We weave high-sliding material for the tubular: Synthetic fibres made of PTFE – so that the shaft slides in the bearing with low friction.

Unlike fabricated tubulars, our tubular fabrics have neither seams nor welds, because we weave them directly as seamless tubulars on our special looms. Our tubular fabrics are therefore not only particularly resilient and burst-resistant. They also have precisely the same material thickness all around. Plain bearings with our industrial textiles – whether for apparatus engineering, the automotive industry or equipment technology – therefore have major advantages: The bearings do not require lubricants, the shaft runs completely evenly, they are durable, they are lightweight, they operate quietly and save energy – and they can be operated maintenance-free.

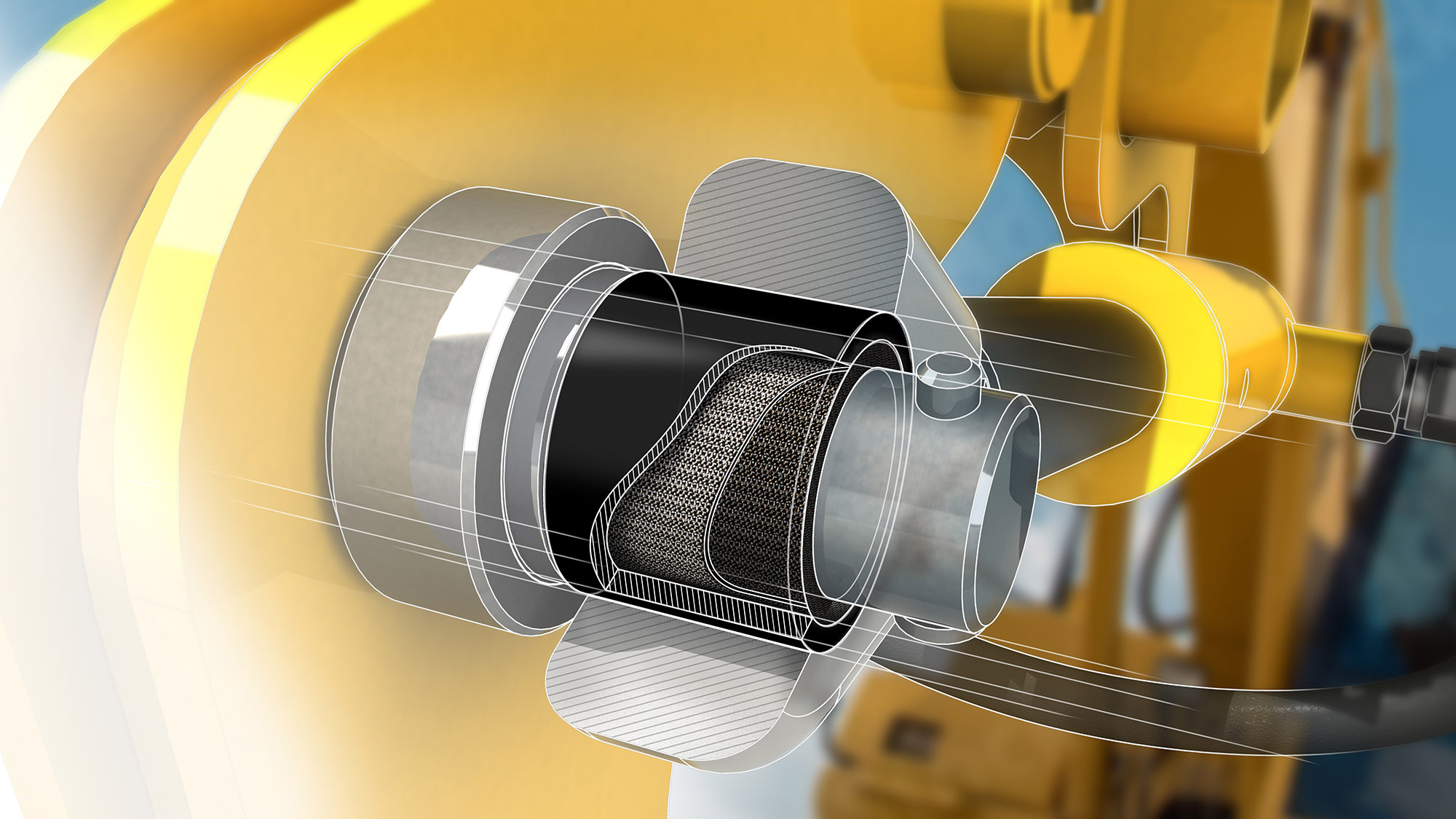

vombaur’s plain bearing tubulars

Tubular made of two layers of material for maintenance-free plain bearing

vombaur textiles for safe processes

“Using the latest system technology, we at vombaur are able to produce narrow textiles with a circumference of up to 3 metres for our industrial customers. Seamless tubulars that are extremely resilient and durable,” emphasises Head of Sales Tomislav Josipovic. “This way, our industrial textiles ensure safe production processes and reliable performance in the system or equipment.”

Illustrations and photos: vombaur