Energy consumption down, performance up

22.11.2022

Preforms from vombaur increase performance and service life:

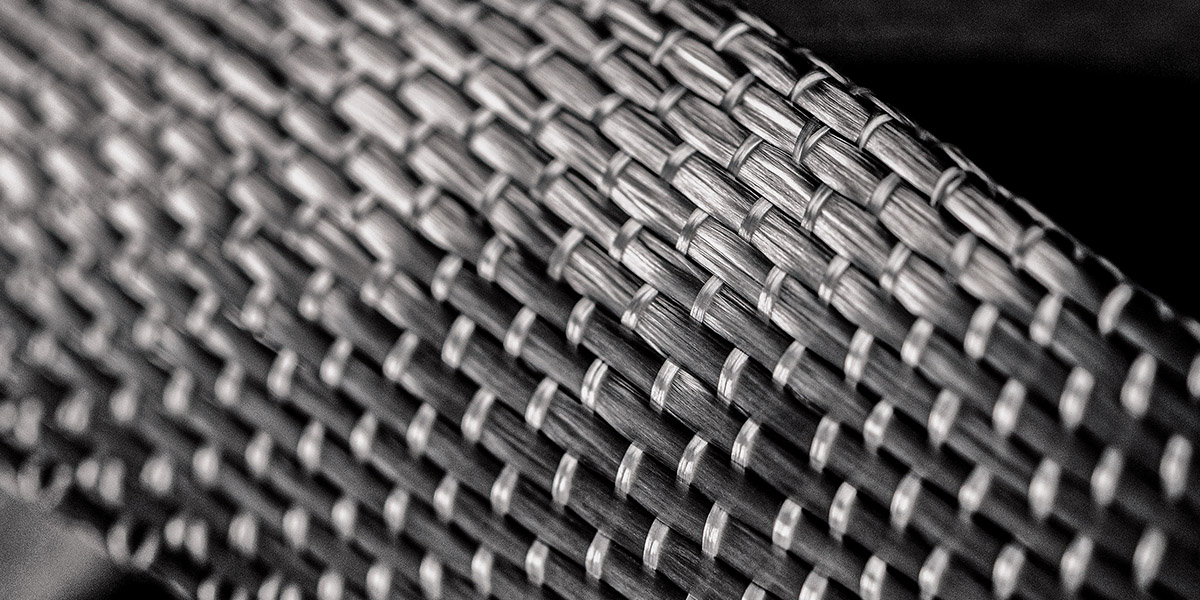

Textiles are lightweight and flexible. The advantages of fibre-reinforced materials have been utilised in aircraft and vehicle construction for many years. In times of energy scarcity and rapidly rising energy costs, many other industries are discovering the innovation and savings potential of lightweight components. Thanks to their high fibre volume content, components made of composite textiles from vombaur offer particularly lightweight and resilient components – in all conceivable shapes and with individual properties.

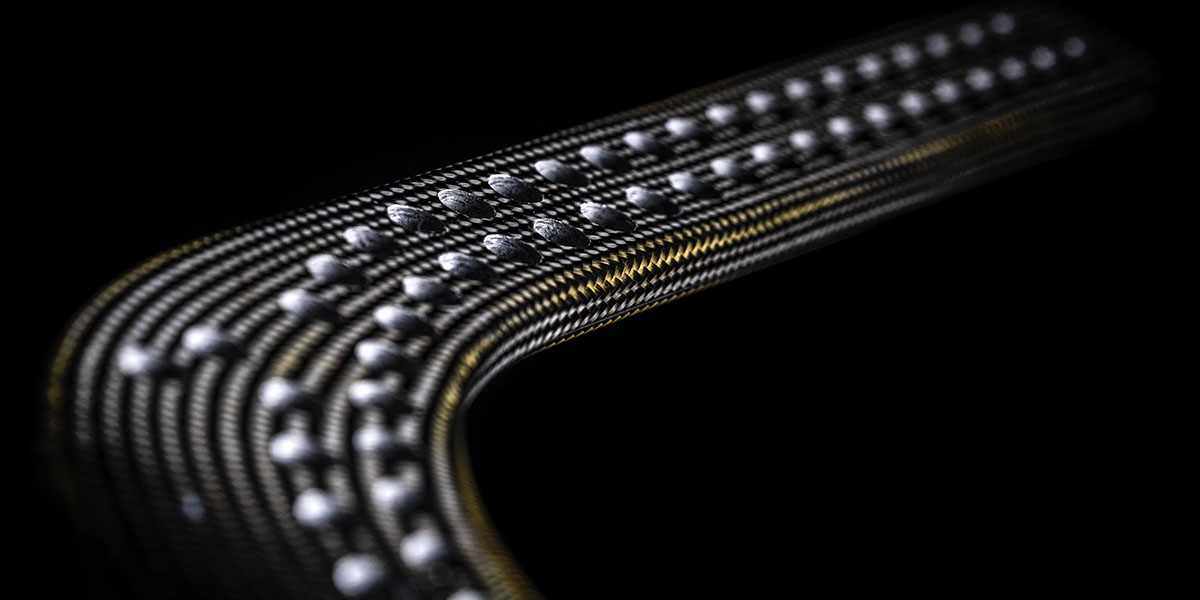

vombaur preforms for maximum weight savings

We develop special preforms made of unidirectional fibre bundles for our customers, with which a fibre volume content of up to 65 percent can be achieved in the component. The fabrics are often made of carbon, but not always. The weft thread is reduced as much as possible in an attempt to reduce the undulation of the fibre bundles and thus optimise load absorption. Our round and shaped fabrics are woven seamlessly.

Components made of composite textiles from vombaur …

- are extremely lightweight

- are high tensile

- are particularly stable and resilient

- are highly efficient

- are easy to process

- work almost vibration-free

- reduce energy requirements

- reduce the use of matrix

- offer excellent damping properties

- provide a long service life

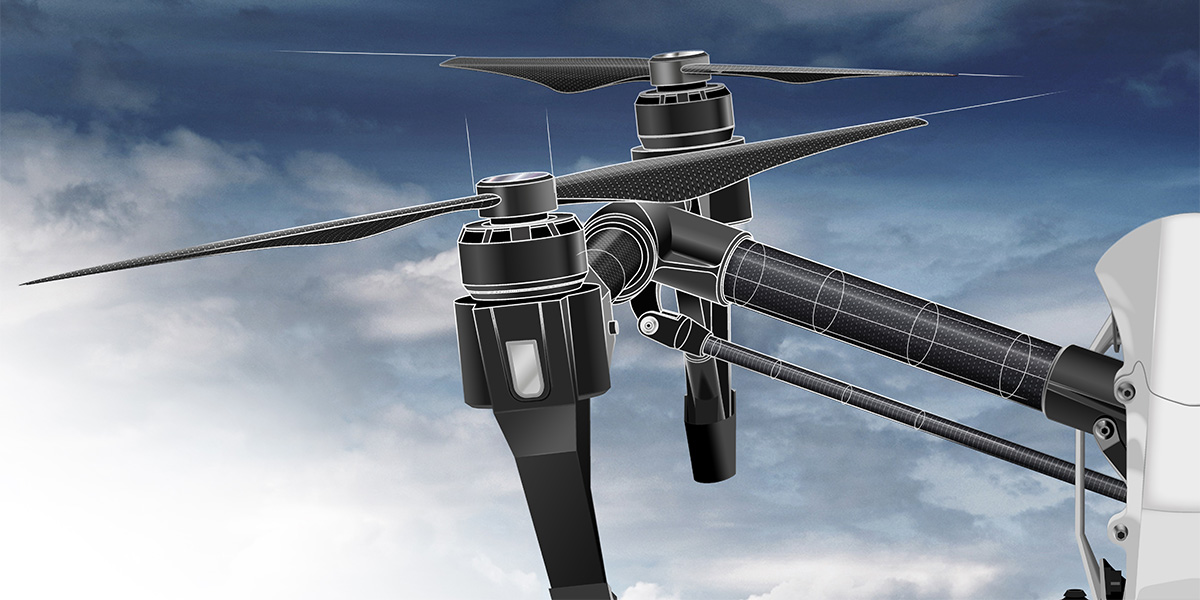

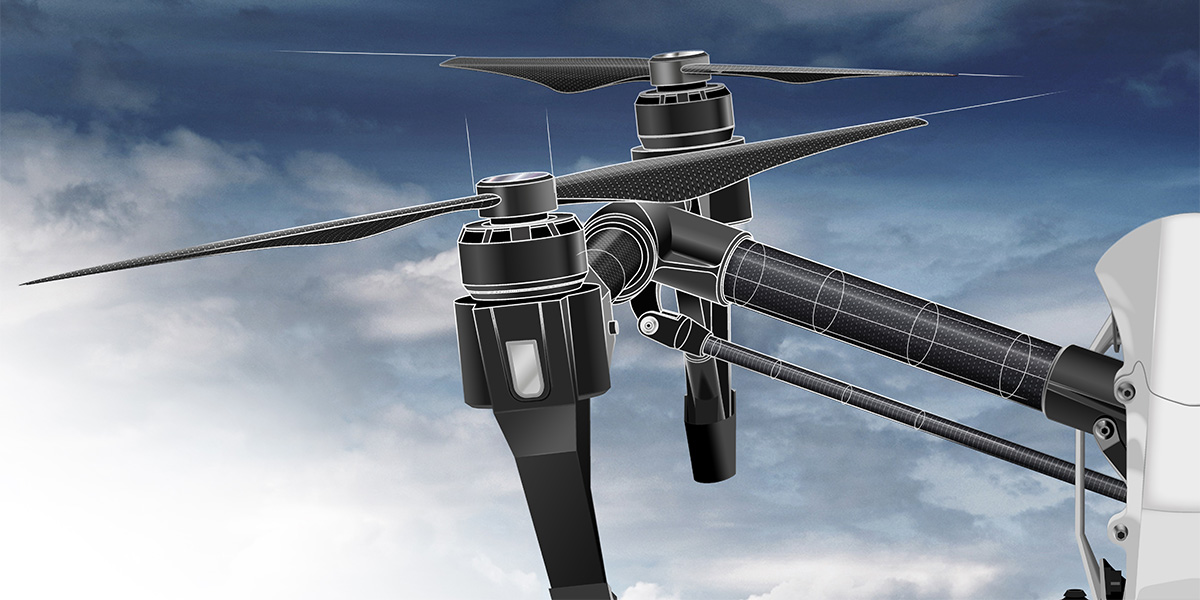

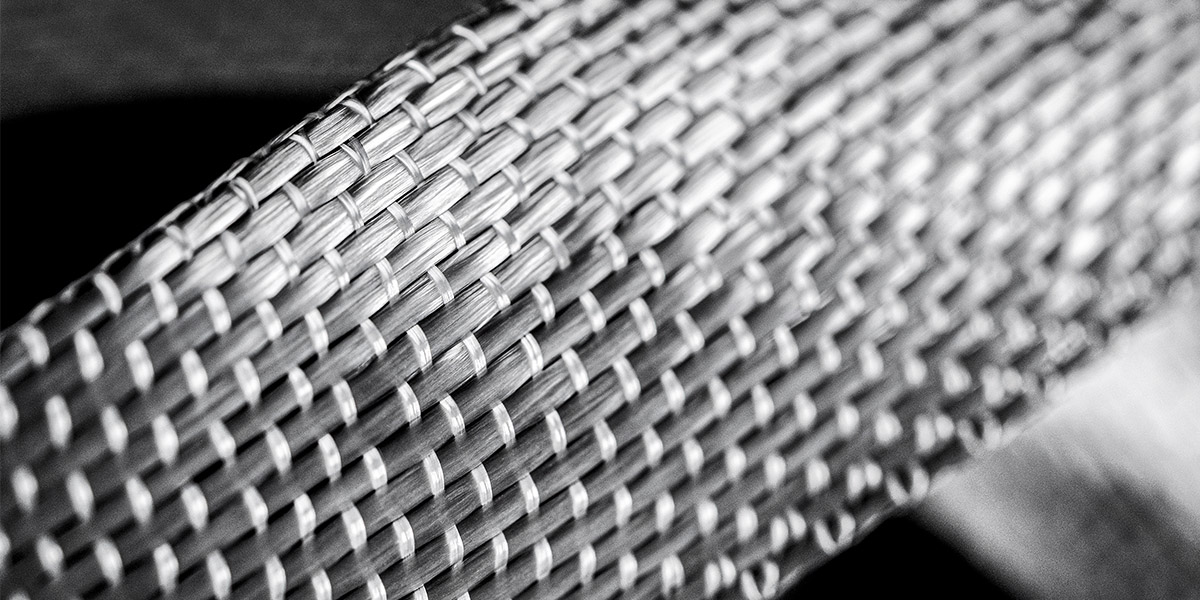

For aviation: ultralight and ultra-flexible

From drone to spaceships. Anything that is supposed to resist gravity has to be extremely lightweight. At the same time, the demands on form, safety and precision in aviation are enormously high. As a development partner and specialist for seamless circular and shape-woven textiles, we supply the textile architecture for high-tech components made of fibre-reinforced materials.

High-tech textiles for high-tech components: composite textiles from vombaur for aircraft construction.

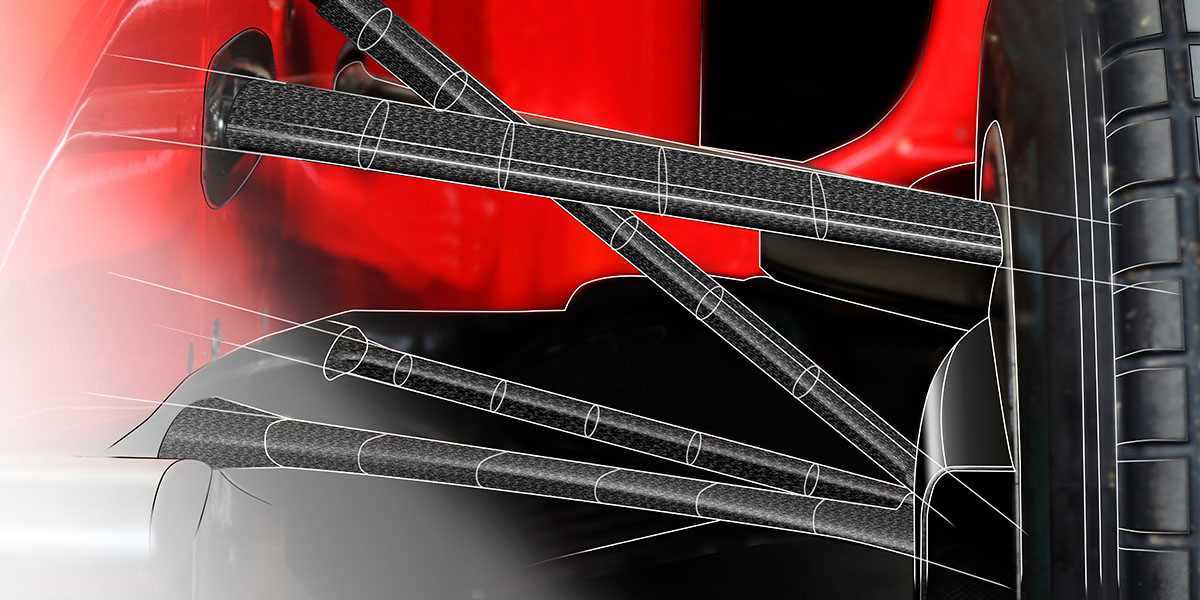

For the automotive industry: extremely light and extremely robust

It is impossible to imagine the automotive industry without our high-tech textiles. The lightweight, yet resilient lightweight components are used in demanding applications – such as the chassis of special vehicles. The customised fibre frame comes from us.

vombaur has developed new production lines for particularly complex preforms.

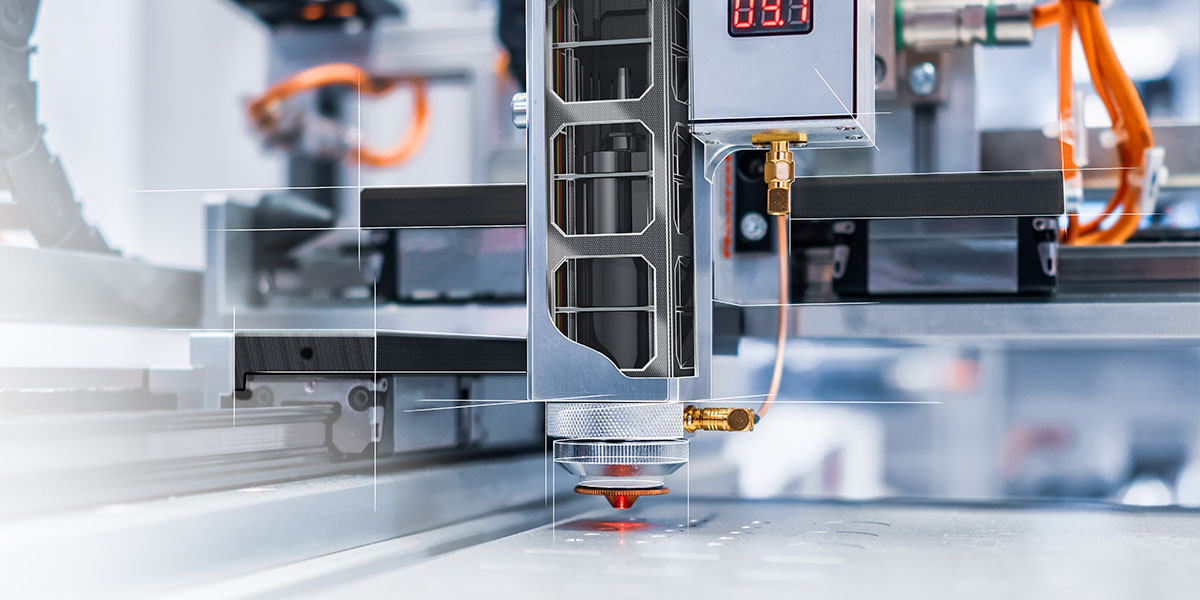

For mechanical engineering: highly efficient and extremely precise

vombaur preforms are used in mechanical engineering, for example, in robot arms, in laser, cutting and milling machines. They impress in this area not only thanks to their light weight, but above all through the damping qualities and the high precision of the system parts. The specific combination of fabric and matrix ensures material properties of component that are precisely matched to the task at hand.

Fibre composite components increase the precision and service life of the plant systems.

“The mechanical properties of fibres open up fantastic possibilities for the development of lightweight components. As a development partner, we specify the fibre type, fibre architecture, weave and powder coating of the high-tech fabrics according to the respective use of the preforms,” explains Dr.-Ing. Sven Schöfer, Chief Technology Officer of vombaur. “This is how we create components with individual, highly complex shapes and properties.”

Illustrations and images: vombaur