Fine and flexible. Safe and precise.

01.06.2021

Textiles for demanding filtration processes in the chemical industry

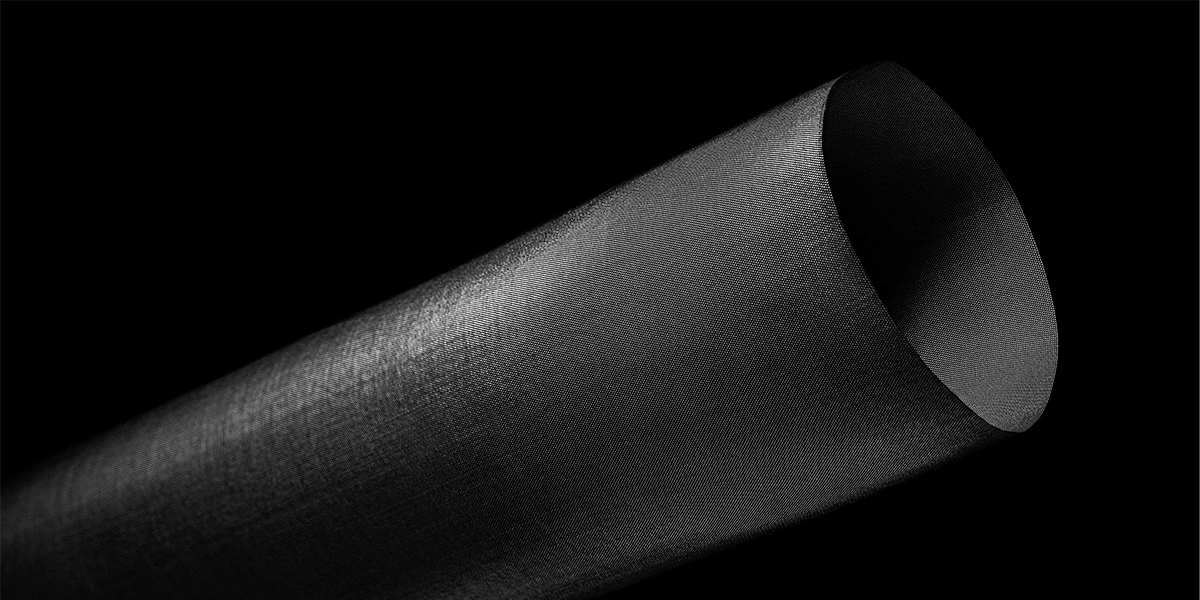

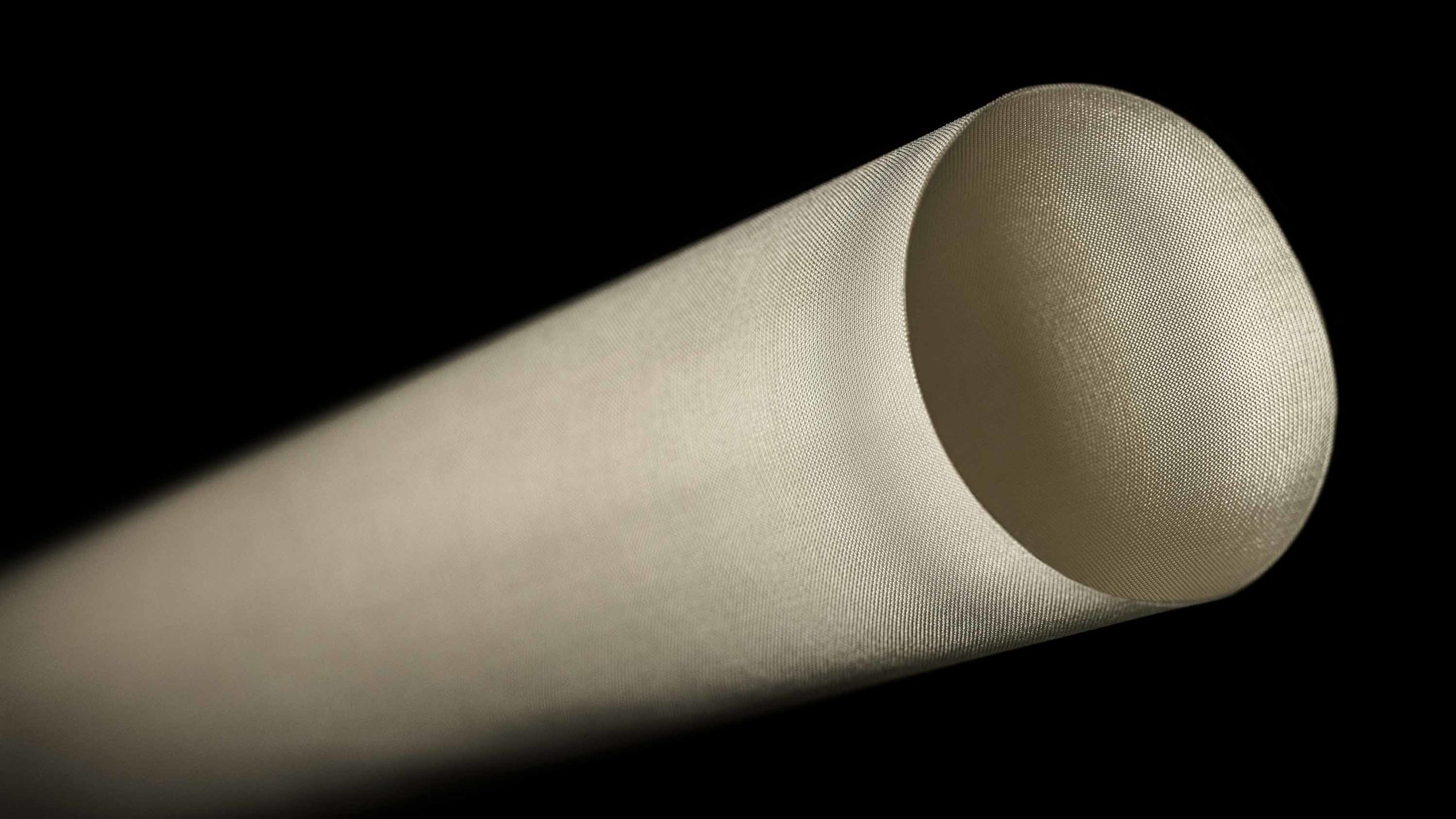

Regardless of whether we are talking about cross-flow or kieselguhr filtration, a horizontal boiler filter or vertical depth filter, or whether it is a small laboratory or large-scale operation – the heart of every filtration system is the actual filter itself. The most widely used filter materials include textiles such as our round woven tubular filters and woven tapes. As a particularly fine and flexible medium that is permeable to fluid, these materials are often used in the chemical industry.

High demands placed on technology and quality – Seamless solutions

Quality, safety and environmental aspects have always played a special role in the chemical sector – and these requirements and standards will continue to rise. Filter systems that are used for chemical production must be state-of-the-art. At all times and in every respect. Filtration must be safe, precise and variable with regard to the finest nuances of separation. The filtration product should be gently separated. At the same time, the durability and lonevity of the medium are also important – especially when it is exposed to high mechanical loads, e.g. as a result of frequent backwashing. From microfiltration processes used in the production of pharmaceuticals to oil filtration in petrochemical applications: a high-tech filter medium is required. A filter medium such as our seamless round and shaped woven filter media..

Uniform surface properties – Optimal filtration result.

The unique production method we employ in our facilities ensures our tubular filters do not have any seams or beading. They therefore exhibitidentical surface properties: all around and over the entire length: there are no fluctuations in terms of shrinkage behaviour or material thickness. The defined flow rate is thereby ensured at every point. The level of resilience is extremely high throughout. Our tubular filters ensure an even filtration process, a homogeneous filter cake and an optimal filtration result.

High-tech fibres – for high-tech processes

Your respective process requirements determine our product development phase. We select the fabric type, weaving technique, finishing and material for our tubular filters and woven tapes, depending on what your filter needs to achieve. We produce high-performance textiles for demanding filtration processes.

Round woven tubular filters and tapes by vombaur for demanding filtration processes in the chemical industry

Round woven tubular filters and tapes by vombaur for demanding filtration processes in the chemical industry

Filtration textiles by vombaur

Development partner for the chemical industry

“Whether it’s in the petrochemical or pharmaceutical industry, the plastics or detergent production sector – the filtration applications required for the chemical industry are extremely demanding. And they differ significantly”, emphasises Sales Manager, Gert Laarakker. “Our high-performance filtration textiles allow us to support all sectors of the chemical industry. As a development partner, we will find the optimal solution for you. Always a perfect fit. Always seamless.”